Diamond saw blade is a cutting tool made of diamond abrasive. Due to its extremely high hardness and wear resistance, it is widely used to cut various hard and brittle materials.

1. Structure:

Diamond saw blade mainly consists of two parts: base and blade head:

Base (Steel Core/Body): Usually made of high-strength steel, it is the main body of the saw blade, providing support and rigidity. There are mounting holes on the base for fixing on the cutting equipment. In order to reduce noise and vibration, some bases will adopt a sound-absorbing design, such as grooving or filling special materials on the base.

Segment/Rim: It is the part of the saw blade that cuts, which is made of a mixture of diamond abrasive and binder. Diamond particles are embedded in the binder to form a sharp cutting edge. The shape, size, diamond particle size and binder formula of the blade head will affect the cutting performance of the saw blade.

2. Type:

Diamond saw blades can be divided into many types according to different classification standards:

According to the cutting method:

Dry Cutting Blade: Suitable for cutting without water or with a small amount of water cooling, usually used for cutting tiles, bricks, etc.

Wet Cutting Blade: Water cooling must be used for cutting to reduce the temperature of the blade, improve cutting efficiency and saw blade life, usually used for cutting stone, concrete, etc.

According to the shape of the blade:

Continuous Rim Blade: The blade is in a continuous ring shape with a smooth cutting surface, suitable for cutting fragile materials such as tiles and glass.

Segmented Rim Blade: The blade consists of multiple independent blade segments, with gaps between segments, which is conducive to chip removal and heat dissipation. It is suitable for cutting materials with higher hardness such as concrete and stone.

Turbo Rim Blade: The blade is wavy or turbine-shaped, with the advantages of continuous blade and segmented blade, fast cutting speed, good chip removal effect, suitable for cutting a variety of materials.

According to the application field:

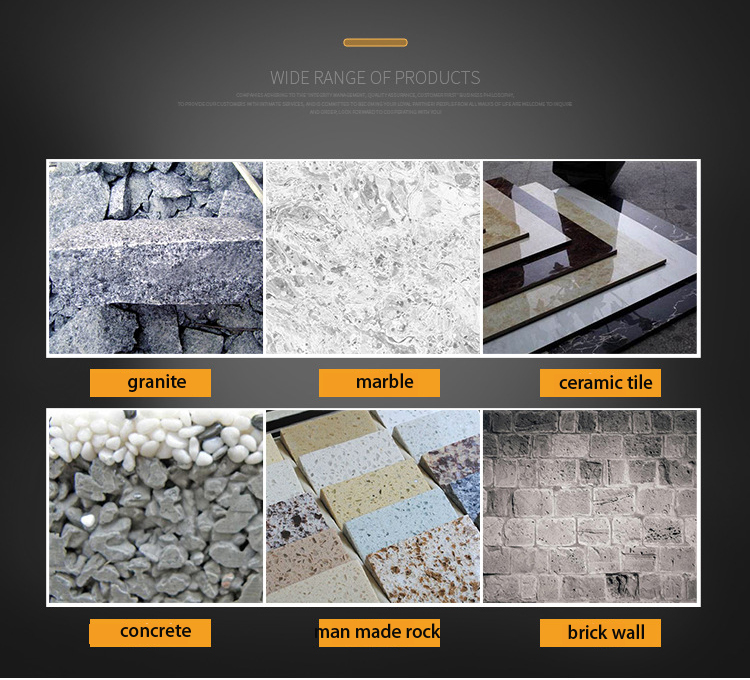

Stone cutting disc: used for cutting granite, marble and other stones.

Concrete cutting disc: used for cutting concrete, reinforced concrete, etc.

Tile cutting disc: used for cutting tiles, ceramics, etc.

Glass cutting disc: used for cutting glass.

3. Feature

1. Extremely high hardness: Diamond is the hardest substance in nature, which allows diamond saw blades to cut objects that are difficult to cut with other materials, such as stone, concrete, ceramics, etc.

2. Excellent wear resistance: Diamond has high wear resistance, so diamond saw blades have a longer service life than other types of saw blades.

3. Sharp cutting edge: The cutting edge of diamond saw blades is very sharp, which can achieve fast and precise cutting.

4. Multiple specifications and types: Diamond saw blades are available in a variety of different specifications and types to suit different cutting needs and materials.

3. Application field:

Diamond saw blades are widely used in the following fields:

Construction industry: cutting concrete, bricks, tiles, stones, etc.

Stone processing industry: mining, cutting, carving various stones.

Ceramic processing industry: cutting tiles, ceramic products, etc.

Glass processing industry: cutting various glass products.

Road and bridge construction: cutting asphalt, concrete pavement, etc.

ADD:

No. 1003 Building 9, Henan E-commerce Industrial Park, High-tech Zone, Zhongyuan District, Zhengzhou, ChinaTEL/FAX:

+8619937510087WhatsApp:

+8619937510087Email:

info@yihongabrasives.com

PRODUCT

FRIENDS LINKS

Quick consulting

Copyright ©Jia County Yihong Abrasives Co.,Ltd All Rights Reserved. Technical Support By Yihong Century Network Technology Co., Ltd. Sitemap

Wechat Service