1.Classification of sand belt——Different structural form

No joint sand belt: with special cylindrical cloth as the base material, through a series of processes made. Because the sand belt substrate has no joint, uniform thickness and no vibration impact during operation, it is especially suitable for fine-grained polished products.

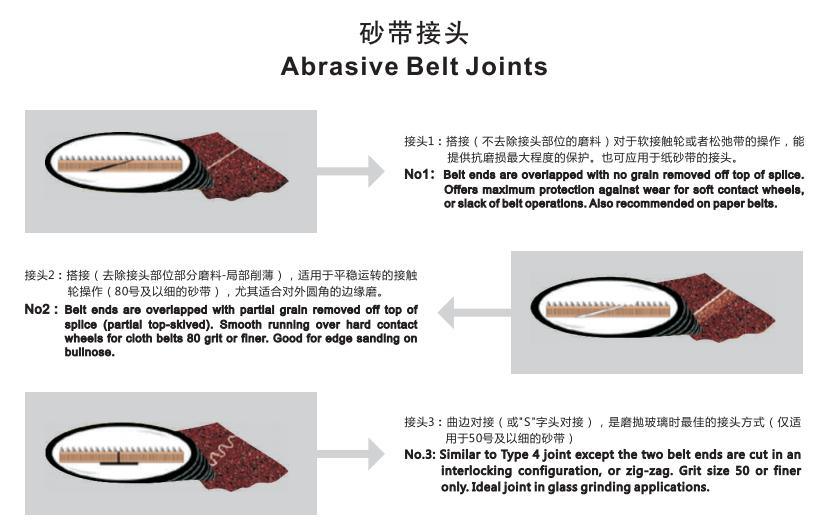

Joint sanding belt: The final product formed by the rolling blank made according to the special requirements of the sanding belt through the conversion process of cutting, edging, joint bonding and slitter. The girth of the joint sand belt is not limited, and it is easy to make and use.

2.Classification of sand belt ——different characteristics

Coated abrasives sand belt: the abrasives are close to each other, the entire surface of the substrate is covered, and there is no obvious gap between the abrasives. Mainly used for difficult grinding processing.

Open abrasives sand belt: the distance between abrasive particles is arranged according to the preset distance, and there is a more obvious gap between single abrasive particles. It can reduce the blocking of grinding chips and is suitable for some specific processing occasions.

Dry sanding belt: widely used, often used in processing applications that do not require coolant.

Water sanding belt: Coolant is required to be added to all processing to reduce workpiece heating and avoid thermal burns.

To sum up, the classification of sand belt is diverse, and users should consider the specific processing needs, workpiece materials, processing environment and other factors when choosing sand belt.

ADD:

No. 1003 Building 9, Henan E-commerce Industrial Park, High-tech Zone, Zhongyuan District, Zhengzhou, ChinaTEL/FAX:

+8619937510087WhatsApp:

+8619937510087Email:

info@yihongabrasives.com

PRODUCT

FRIENDS LINKS

Quick consulting

Copyright ©Jia County Yihong Abrasives Co.,Ltd All Rights Reserved. Technical Support By Yihong Century Network Technology Co., Ltd. Sitemap

Wechat Service