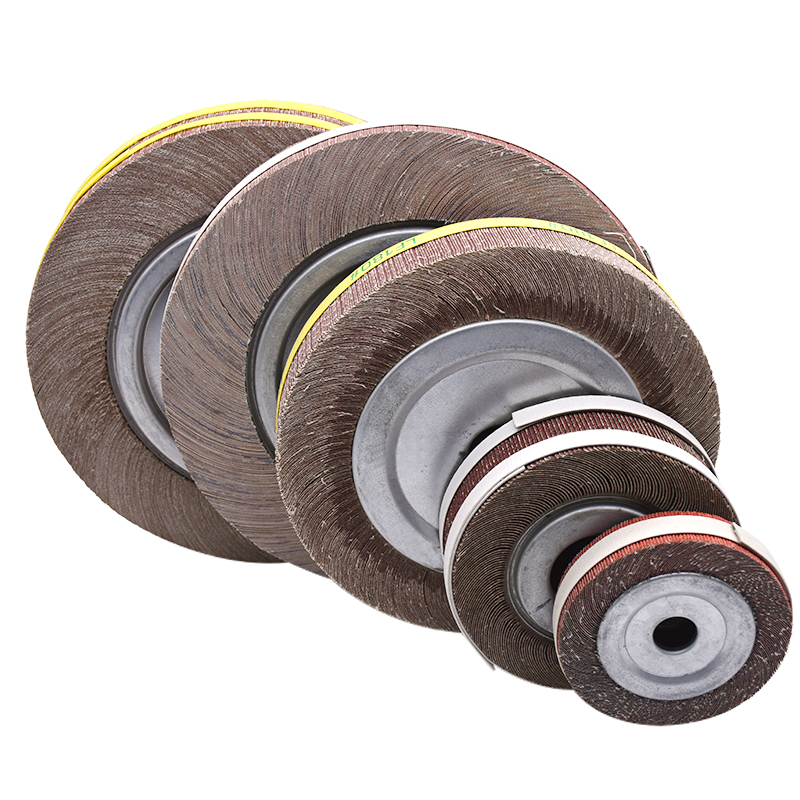

Different flap wheels

According to the type of abrasive used, flap wheel can be divided into four types: Aluminium oxide flap wheel,zirconia alumina flap wheel,calcined aluminium oxide flap wheel,silicon carbide flap wheel. In addition, there is a shaft flap wheel.

1. ALUMINIUM OXIDE FLAP WHEEL

Aluminium Oxide Flap Wheel has universal design for easy mounting ,high cut rate,good adhesion for high speed and ideal for the surface treatment.

Suitable for grinding, polishing, finishing, derusting of cookware making, automobile manufacturing, heavy machinery,shipbuilding, steel, aluminum alloy, hardware and decorative industries.

2. ZIRCONIA ALUMINA FLAP WHEEL

The Zirconia Alumina Flap Wheel is engineered for fast cutting and good elasticity, ensuring a sharp cutting action that is both stable and safe, which is crucial for high-efficiency operations. It also provides a superior finish and flexibility, making it an excellent choice for various grinding and finishing tasks.

Suitable for grinding, polishing, finishing, derusting of cookware making, automobile manufacturing, heavy machineryshipbuilding, steel, aluminum alloy, hardware and decorative industries.

3. CALCINED ALUMINIUM OXIDE FLAP WHEEL

The Calcined Aluminium Oxide Flap Wheel is a general-purpose tool, renowned for its ease of continuous operation and high working efficiency, which translates to a long service life and reliable performance in various grinding applications.

Suitable for grinding, polishing, finishing, derusting of cookware making, automobile manufacturing, heavy machinery,shipbuilding, steel, aluminum alloy, hardware and decorative industries.

4. SILICON CARBIDE FLAP WHEEL

Silicon carbide flap wheel has high working efficiency andStable grinding quality.It will not burn the workpiece during use.

Suitable for grinding, polishing, finishing, derusting of cookware making, automobile manufacturing, heavy machineryshipbuilding, steel, aluminum alloy, hardware and decorative industries.

5. SHAFT FLAP WHEEL

The Shaft Flap Wheel is designed for easy and safe operation, offering excellent flexibility that allows it to conform to various shapes during the grinding process. It is convenient to install, ensuring a swift setup for your machinery. With its fast cutting capabilities, it provides efficient material removal, and it operates with low noise and minimal clogging, making it an optimal choice for a smooth and quiet work environment.

Suitable for finishing, light deburring, cleaning or preparation for subsequent treatments on small or hard-to-reach surfaces. Widely used for workpiece assembly, mould manufacturing, metal fabrication, welding and polishing industries.

ADD:

No. 1003 Building 9, Henan E-commerce Industrial Park, High-tech Zone, Zhongyuan District, Zhengzhou, ChinaTEL/FAX:

+8619937510087WhatsApp:

+8619937510087Email:

info@yihongabrasives.com

PRODUCT

FRIENDS LINKS

Quick consulting

Copyright ©Jia County Yihong Abrasives Co.,Ltd All Rights Reserved. Technical Support By Yihong Century Network Technology Co., Ltd. Sitemap

Wechat Service