1.What is Abrasive Velcro Discs?

Velcro disc, also known as velcro disc sandpaper or adhesive sandpaper, is a product produced by flocking the back of a large roll of sandpaper and then stamping it by a punching machine with various types of knife dies. It has the following characteristics:

1. Back flocking : The back of the velcro disc is planted with flannelette, which makes it easier to replace than the back rubber disc sand, improving the grinding efficiency.

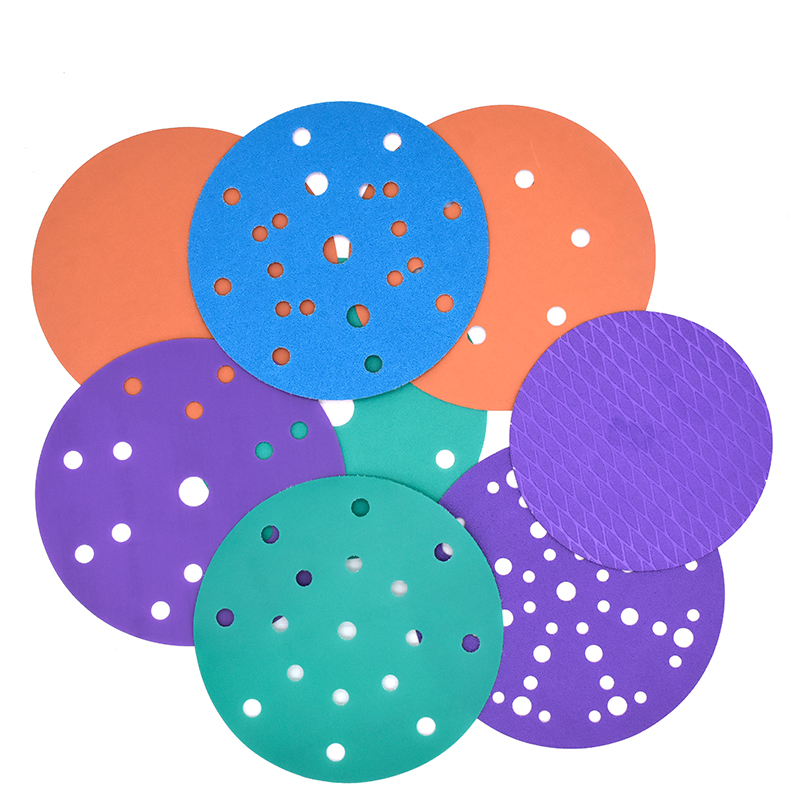

2. Various shapes : The common specifications are round, rectangular, triangle and other shapes, and can also be made into a vacuum hole.

3. Sand surface classification : According to the color of the sand surface, there are red, white, yellow, green, blue, black and other different colors of sand surface.

4. Raw materials : sandpaper raw materials are divided into silicon carbide, alumina and zirconium corundum, silicon carbide is divided into green silicon carbide and black silicon carbide, alumina is divided into brown corundum and white corundum.

5.Widely used : velcro discs are widely used in automotive, hardware, electronics, furniture, plastics, crafts and other fields, faster than hand grinding products, higher efficiency, better effect.

6. Can be polished in water : velcro disc can be polished in water, which improves the wear resistance to a certain extent.

7.Easy to replace and use : Due to the flocking design on the back, the velcro disc is easy to replace in use, and can quickly adapt to different grinding needs.

8. Suitable for a wide range of machines : velcro disc can be used on common machines and are capable of using different materials, suitable for all applications from surface grinding to the grinding of highly formed parts.

In summary, the velcro disc is an efficient and versatile sanding tool suitable for a variety of materials and scenarios.

2.What are the advantages of using velcro discs?

Applicable to a variety of materials: velcro disc are suitable for a variety of materials, including general metals, wood and wood, coatings/paints/fillers, steel, non-ferrous metals, plastics, stainless steel, glass, aluminum, titanium, leather, mineral materials, etc.

High removal rate and long service life: Users benefit from high removal rate and long service life when using velcro disc, which is an important factor for professional applications in trade, industry and construction.

High cost performance: the velcro disc has good grinding effect, high cost performance, and it is more conducive to the later painting process after grinding.

Reduced clogging and long service life: Heavy duty paper backing with Vicronon flannelung buckle reduces clogging and has a long service life.

Suitable for a variety of jobs: whether used in track sanders, random track sanders, triangle sanders or on hand boards, these products have the same efficiency

What are the differences between brushed plates and sandpaper?

Velcro disc and ordinary sandpaper are two common sanding tools, and they have some differences in structure, use and application scenarios:

Structural differences:

velcro disc: Usually has a flocking back that can be replaced quickly and is suitable for electric sanders. They are usually designed to be quickly attached to the disc of the sander for easy replacement and use.

Sandpaper:Usually a piece of paper with sand particles, which can be dry or wet. Sandpaper can be used by hand or with tools such as sandpaper clamps.

How to use:

Flapping dish: Because there is flocking or adhesive on the back, it can be directly pasted on the disc of the sander, suitable for electric grinding, easy to replace, suitable for fast grinding.

Sandpaper: It can be used manually or with sandpaper clips and other tools. Wet sandpaper can be used in water, while dry sandpaper cannot.

Durability:

velcro disc: Due to its structure, it is usually more durable than ordinary sandpaper and is replaced less frequently.

Sandpaper: Durability depends on the quality of the sandpaper and how it is used, and usually needs to be replaced more frequently.

Grinding effect:

velcro disc: Due to its structure, it can provide a more uniform grinding effect and reduce scratches.

Sandpaper: The sanding effect depends on the type of sandpaper and the use of skills, manual use may produce uneven sanding effect.

Application scenario:

Flapping dish: More suitable for power tools, suitable for large area or continuous grinding work.

Sandpaper: More suitable for small areas or fine sanding work, can also be used for hand sanding.

Cost:

velcro disc: May be more economical in the long run due to its durability and ease of replacement.

Sandpaper: Less costly, but may need to be replaced more frequently.

Security:

velcro disc: Due to its rapid replacement nature, the safety risks arising from the replacement of sandpaper can be reduced.

Sandpaper: If not used correctly, such as broken sandpaper or improper use, it can cause safety problems.

Environmental protection:

velcro disc: Due to its durability, it reduces the frequency of replacement and may be more environmentally friendly.

Sandpaper: If you change frequently, you may produce more waste.

ADD:

No. 1003 Building 9, Henan E-commerce Industrial Park, High-tech Zone, Zhongyuan District, Zhengzhou, ChinaTEL/FAX:

+8619937510087WhatsApp:

+8619937510087Email:

info@yihongabrasives.com

PRODUCT

FRIENDS LINKS

Quick consulting

Copyright ©Jia County Yihong Abrasives Co.,Ltd All Rights Reserved. Technical Support By Yihong Century Network Technology Co., Ltd. Sitemap

Wechat Service